Our overriding aim is to continuously develop and provide our customers with the expert completion of their orders. We design all the products ourselves, build the injection moulds and the automation necessary to secure the manufacturing process of our plastic products.

In pursuing our objectives, we always strive to continuously reduce our impact on the environment, thus ensuring its protection.

- we work with state-of-the-art machinery based on energy efficient machines;

- we are powered by a solar farm;

- we design ergonomic products;

- our products are 100% recyclable;

- our product transport is designed to use almost 100% of the transport area.

GET TO KNOW OUR

AREAS OF ACTIVITY

We specialise in the plastic product injection moulding process, which enables us to create packaging of all shapes. This method results in products of the highest quality.

IML (In Mould Labelling) technology consists of an irreversible bonding of the label with the product during the manufacturing process. This gives the product a very high visual impact and ensures the durability of the decoration. If certain conditions are met, IML labelling increases the barrier properties of the product. In addition, products with an IML label can be recycled.

Our basic range includes products for the cosmetic, food, chemical and other industries.

WE HAVE

MODERN MACHINERY

Since the beginning, we have invested in machines that not only increase our manufacturing capacity, but also have no negative impact on the environment thanks to their innovation. For years, we have relied on top-quality equipment. It is thanks to these investments in technology development that we are able to carry out the most demanding projects. Our machinery includes the latest generation of injection moulding machines and accessories. We have fully-automated machine groups, where robots feed the IML label, inspect the part, separate into compliant and defective parts and stack them ready for dispatch.

We have electric, hybrid and hydraulic injection moulding machines with a total of 40 units and mould closing forces from 50 T to 400 T

All machines form separate fully-automated machine groups (robots for IML label feeding, product receiving and stacking, visual inspection of each product)

A toolroom with modern machinery equipped with CNC machines.

Decoration of products on a multicolour offset printing machine

Packaging decoration line for self-adhesive labels

Packaging of hygiene products takes place on 4 production lines

OWN

Transport and logistics

We can provide national and international transport with our own fleet of vehicles, all of which are equipped with GPS tracking systems. There is the option for both side and top loading. We also have all the documents required for domestic and international transport.

The company’s own warehouse and fleet allow us to flexibly tailor deliveries to specific customer needs.

Our third-party insurance cover amounts to EUR 1,000,000.

Domestic and international transport

Own car fleet

Own warehouse

OCP insurance

SEE OUR

Certificates

The company is our brand, and the pledge of reliability and the quality of our services is attested by a number of certifications.

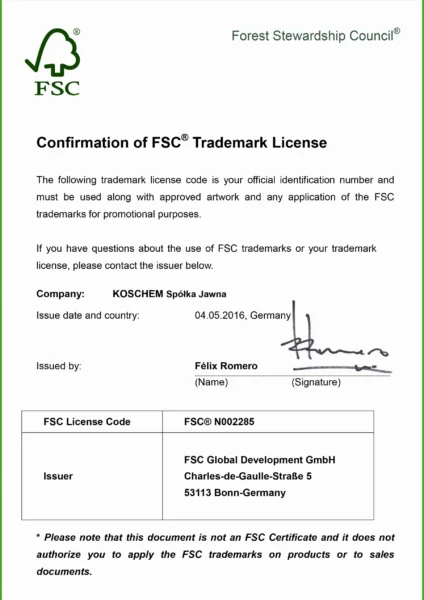

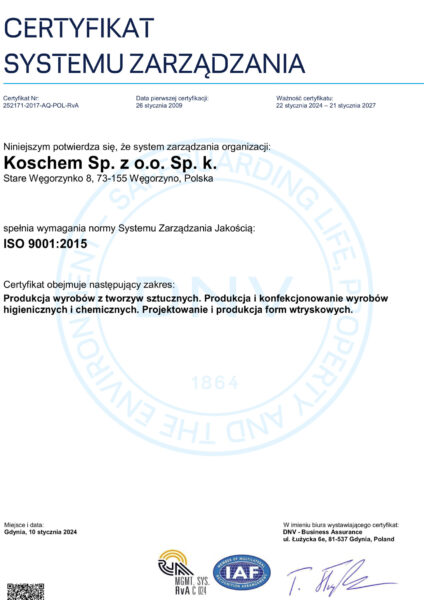

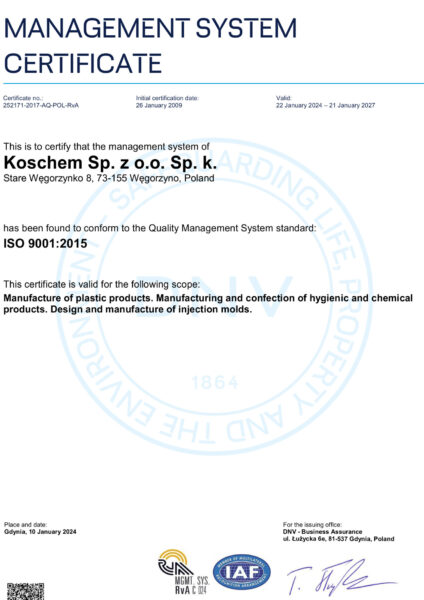

We are ISO 9001:2015 certified by DNV-GL. We comply with GMP requirements, holding complete GMP (Good Manufacturing Practice) and GHP (Good Hygiene Practice) documentation. We have introduced and apply elements of HACCP (for packaging for use in contact with food). As a responsible business, we promote products certified with the FSC label.